What is a Gear Pump

Don’t let the name “gear pump” fool you. Gear pumps are used to transport many other media besides water. We think it will be helpful to review how gear pumps work and tell you about some of their applications.

Don’t let the name “gear pump” fool you. Gear pumps are used to transport many other media besides water. We think it will be helpful to review how gear pumps work and tell you about some of their applications.

A gear pump employs a system of meshing of gears to move fluids. Because of the mechanism involved, gear pumps qualify as positive displacement pumps. For every revolution the gears in a gear pump make, the same amount of fluid is moved.

Due to their design, gear pumps are often used for transporting high viscosity fluids, especially in the chemical industry.

Gear pumps have two gears that separate on the intake side of the pump. This creates a partial vacuum, creating suction which draws fluids into the pump. The gears then carry the fluid through the pump and out the other side, to the outtake. The fluids are displaced by the rotation of the gears. Due to the direction and position of the gears, the fluid can only flow from the intake side to the outtake side.

Applications for Gear Pumps

Gear pumps are mainstays in the petrochemical industry. They are used for crude oil, diesel oil, lube oil, pitch and bitumen. They are also used for transporting chemicals such as sodium silicate, mixed chemicals, acids, plastics, isocyanates and other chemicals that must be handled with care.

They are also used for adhesives, resins, ink and paint. They are especially popular in the pulp and paper industries, where they are used for acid, lye, soap, black liquor, latex, kaolin, lime and sludge.

The food industry uses them for a lot of tasty options, including molasses, vegetable oils, pet food, vegetable fats, fillers, sugar, chocolate and cacao butter.

Types of Gear Pumps

Positive Displacement Pump

The positive displacement pump provides an approximate constant flow at fixed speed, despite changes in the counter pressure.

Positive displacement pumps all pulsate, meaning that their volume flow within a cycle is not constant. The variation in flow and speed leads to pressure fluctuations due to resistance in the pipe system and in valves.

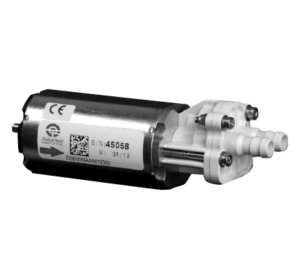

Dosing Pump

Dosing pumps can be set to discharge exactly the quantity of dosing liquid required for the required application.

Applications include drinking and waste water treatment, industrial applications and the food and beverage industry.