What is a Submersible Pump

What is a Submersible Pump

Submersible pumps consist of a pump body with a hermetically sealed motor attached to it.

This allows the pump to be safely submerged in fluids without compromising the motor. The design prevents the pump from cavitation and is considered to be more efficient than a jet pump. Jet pumps are surface mounted and pull fluid from below the ground while submersible pumps are located in the fluid and push fluid.

Submersible pumps are used for pumping Groundwater, Dewatering applications, Transfer of Fluid, Agitation of Fluid, to provide water for Irrigation as well as Drinking or Plant Process Water. They are used in Drilling Systems, Waste Water Systems, and Waste Water Treatment systems.

Applications for Submersible Pumps

Submersible pumps are used in nearly all industries including Mining, Oil & Gas, Commercial, Food Processing, Industrial, Medical / Hospitals, Municipal, petrochemical, Water Supply & Water Treatment, Residential.

Classes of Submersible Pumps

Aerators

Aerator pumps are submersible water pumps that inject air into water. They are used primarily for wastewater treatment and for aerating water in ponds or aquafarms, but can be used anywhere water lacks oxygen, often referred to as being in “anoxic condition.”

Tsurumi BER Series

The powerful single direction jet current of the BER series is unrivaled in vertical stirring convection. In addition, its required shaft power is not so much changed when the depth changes.

Read MoreGorman Rupp Echostorm

A static venturi aeration device designed to add dissolved oxygen to liquids in a variety of industrial and municipal wastewater applications.

Read MoreBorehole Pump

Borehole pumps are a class of submersible pumps used to control water and liquid supply in agricultural, mining, municipal and petrochemical applications.

Borehole pumps are also known as bore pumps, well pumps or bore water pumps.

Lowara eGS Series

The eGS series from Lowara has been designed to meet the needs and demands of the following applications:

Read MoreLowara Z Series

The Z range of pumps are submersible borehole pumps suited to be installed in bore casing from 6".

Read MoreCalpeda 6SDX

The Calpeda 6SDX range are submersible borehole pumps for 6” wells (DN 150 mm) and 8” (DN 200 mm).

Read MoreCalpeda 4SD, 4SDF

This range from Calpeda includes submersible borehole pumps for 4” wells (DN 100 mm), and 6” (DN 150 mm), with external jacket in stainless steel AISI 304 and stages in polycarbonate for 4SD pumps and in noryl for 4SDF, 6SD, 6SDN pumps.

Read MoreCalpeda 4SDP

Submersible borehole pumps for 4” wells (DN 100 mm), with external jacket in stainless steel AISI 304 and stages in Noryl.

Radial floating impeller with high reliability operating in sandy water.

Read MoreCalpeda SDX

Stainless steel construction designed and built for years of trouble free operation designed and built to operate in difficult conditions. Suitable for pumping clean, thin, non-aggressive and non-corrosive liquids without solid particles or fibres. 4SDX, 6SDX, 8SDX and 10SDX models available.

Read MoreEbara 4N Series

The EBARA 4N Series is a submersible borehole pump with closed impellers designed to pump clear water

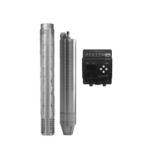

Read MoreGrundfos SP Series

The SP range of pumps are submersible borehole multistage pumps suited to be installed in bore casing from 4"

Read MoreGrundfos SQEN Series

The SQEN range of pumps are the most compact submersible borehole multistage pumps suited to be installed in bore casing from 3".

Read MoreGrundfos SQN Series

The SQN range of pumps are the most compact submersible borehole multistage pumps suited to be installed in bore casing from 3".

Read MoreSlurry Pump

A slurry pump is a class of centrifugal or submersible pump designed for pumping liquid containing solid particles.

Slurry pumps are subject to additional wear and are commonly more robust than other pumps. Slurry pumps can be electrically or hydraulically driven.

Tsurumi GPN Series

The GPN series is not only durable but offers longevity courtesy of a special-steel impeller and suction plate.

Read MoreTsurumi GSZ Series

Tsurumi's GSZ series features a range of powerful high-volume pumps with a special-steel impeller and a 6-pole motor.

Read MoreTsurumi HSD Series

The HSD is easy to maintain and has been designed specifically for draining sand-carrying or silt laden water in general construction or similar works.

Read MoreTsurumi NKZ Series

The NKZ series of high head sand pumps have a spiral pump casing and a shaft mounted agitator for smooth suction of slurry, mud or sand.

Read MoreKRDX Explosion Proof Submersible Pump

The KRDX-series is a submersible three-phase heavy-duty explosion-proof slurry pump driven by a 4-pole motor equipped with a high-chromium cast iron agitator that assists the smooth suction of the settled material

Read MoreTsurumi KRS Series

The KRS series belongs to Tsurumi's range of efficient submersible drainage pumps manufactured for general construction work. The pumps are available in 3 different ranges including the:

Read MoreWEDA S Range Sludge Pumps

The WEDA sludge pumps can handle thick, soft, wet mud or other similarly viscous mixtures of liquids and solids, especially the product of an industrial or refining process.

Read MoreWEDA L Range Slurry Pumps

The WEDA slurry pumps are the toughest, and have the largest apertures to facilitate handling of slurry with the most challenging solids.

Read MoreSpindle Pump

A Spindle pump is a class of centrifugal or submersible pump used for handling slurries, liquids with abrasive solids in suspension and severe pumping problems such as corrosion, abrasion and temperature extremes.

Vertical Spindle Pumps (also known as Vertical Sump Pumps) are a semi submerged arrangement with its pump end submerged in the fluid and “bearing column” protruding out the fluid. At the top of the bearings column the mechanical driving mechanism is mounted allowing the pump to operate without the need for mechanical seals. Standard electric motors can be used instead of specialised submersible motors..

Seepex E Series

The E series range of pumps from Seepex consists of semi-submersible pumps that offer high efficiency, a minimal footprint and a maintenance-friendly design.

Read MoreBalz 100 Series

The BALZ 100 series is manufactured from the very best materials available, providing both excellent wear properties and corrosion resistance. High chrome and urethane wear resistance parts ensure excellent results for arduous pumping solutions.

Read MoreBalz 200 Series

Featuring the unique patented bubble sealing system as well as a urethane and rubber pump casing, the 200 series offers excellent performance and wear resistance.

Read MoreBalz 300 Series

Featuring the unique patented bubble sealing system, the 300 series is primed for peak performance and can be configured for varying immersion depths.

Read MoreBalz 400 Series

Wear-resistant, capable of running dry indefinitely and designed with a patented sealing arrangement that prevents media reaching bearings, the 400 series offers durability and efficiency.

Read MoreBalz 500 Series

Fitted, designed and manufactured for heavy-duty effectiveness, the 500 series is a proven pump solution for optimum performance.

Read MoreGrundfos SPK Series

SPK are vertical multistage pumps designed for pumping of cooling lubricants for machine tools, condensate transfer and similar applications. The pumps are designed to be mounted on top of tanks with the chamber stack immersed in the pumped liquid

Read MoreSpeck T-401 / 601

This series consists of sealless vertical pumps that are easy to assemble, affordable and require little maintenance.

Read MoreSpeck TM-201 / 401 / 601 / 701

This series consists of sealless vertical pumps that are easy to assemble, affordable and require little maintenance.

Read MoreSpeck TM-402 / 403 / 602

This series consists of sealless vertical pumps that are easy to assemble, affordable and require little maintenance.

Read MoreSump Pump

A sump pump is class of centrifugal or submersible pump used to remove water that has accumulated in a sump pit.

Vertical Sump Pumps are a semi submerged arrangement with the pump end submerged in the fluid and the bearing column protruding out the top of the fluid. Sump pumps are used for handling slurries, liquids with abrasive solids in suspension and severe pumping problems such as corrosion, abrasion and temperature extremes.

Wastewater Pump

Wastewater pumps are a class of submersible pump that are designed to handle solids-laden wastewater, effluent and sewage.

Solutions are available for domestic municipal, industrial and commercial effluent and wastewater applications.