Also available: Electric Diaphragm Pumps

What is an Air Operated Diaphragm Pump

A diaphragm pump is a positive displacement pump which operates with a flexible diaphragm, and integrated check valves. The diaphragm is moved inward & outward toward the pump body which works in conjunction with the check valves and draws in and expels the fluid out the pump casing.

The most common diaphragm pump is an Air Operated Double Diaphragm (AODD) pump.

The AODD is a form of positive displacement pump in which has two pump chambers, a “left” & a “right”. The left and right chambers each have their own diaphragm which interconnect with a shaft so when the one moves, the other one moves proportionality at the same time.

Applications for Air Operated Diaphragm Pumps

Diaphragm Pumps have a wide variety of applications and uses in many industries including food, dairy, pharmaceutical and cosmetic industries, where Stainless Steel pumps are used for these hygienic requirements.

Air pumps are very commonly used in the food sector as the transfer of the fluid does not disrupt the chemical properties and consistency of products such as milk, buttermilk, yogurt, cream, mustard, mayonnaise, ketchup and similar products.

Other uses of AODD pumps include transfer of petroleum products, oil and sludge removal operation, transfer of many types of chemicals, including adhesives, solvents, solvent and water based glues and adhesives, paints and inks. The diaphragm pump is the preferred option for these and other types of chemicals and are widely used as they have the ability to operate safely in a flammable environment.

Types of Diaphragm Pump Air Operated

Positive Displacement Pump

The positive displacement pump provides an approximate constant flow at fixed speed, despite changes in the counter pressure.

Positive displacement pumps all pulsate, meaning that their volume flow within a cycle is not constant. The variation in flow and speed leads to pressure fluctuations due to resistance in the pipe system and in valves.

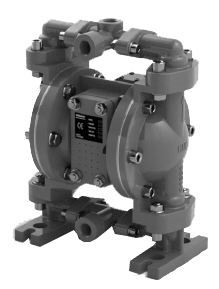

RAN Aluminium Series Diaphragm Pump

The RAN A series of diaphragm pump is an Air Operated Double Diaphragm (AODD) pump manufactured from high-quality Aluminium.

RAN Atex Certified Diaphragm Pump

The RAN ATEX Certified series diaphragm pumps are an Air Operated Double Diaphragm (AODD) that is designed for use in an environment with an explosive atmosphere.

RAN Cast Iron Series Diaphragm Pump

The RAN C series of diaphragm pump is an Air Operated Double Diaphragm (AODD) pump manufactured from high-quality Cast Iron.

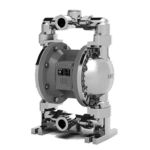

RAN Cast Stainless Steel Diaphragm Pump

The RAN SC series of diaphragm pump is an Air Operated Double Diaphragm (AODD) pump manufactured from high-quality Cast Stainless Steel. They suitable for a variety of applications in many industries such as water transfer, chemicals, paper/pulp, paints, waste water, ceramics, construction, mining, shipping etc.

RAN High Pressure Diaphragm Pump

RAN High pressure pneumatic pumps offer uniquely efficient operations and are suitable for a variety of uses. The self priming high pressure unit is operated with a single diaphragm pump and has ball & seat check valves.

RAN Polypropylene Series Diaphragm Pump

The RAN P series pneumatic diaphragm pump is a Polypropylene Air Operated Double Diaphragm (AODD) pump designed to handle a wide range of substances.

RAN PVDF Series Diaphragm Pump

The RAN PV series of diaphragm pump is an Air Operated Double Diaphragm (AODD) pump manufactured from PVDF material. They can be used to pump hazardous materials, chemicals, slurries and even solids.

RAN Stainless Steel Food Grade Diaphragm Pump

The RAN S series of diaphragm pumps is an Air Operated Double Diaphragm (AODD) pump manufactured from high-quality Food Grade Stainless Steel. They are FDA approved.