What is a Vacuum Pump

Vacuum pumps move air, powders, fluids etc, by creating a vacuum.

When air is removed from a sealed space, it creates a pressure deficit which allows the product to flow into that space. In other words, the product moves from a place of higher pressure to a place of lower pressure.

The first vacuum pump was created in approximately 1650, but it is likely that suction pumps have been in existence for thousands of years, because a bamboo reed used as a straw would qualify as a primitive, man-powered suction pump.

Vacuum pumps are usually classified in one of three basic categories: positive displacement, entrapment or momentum transfer, also known as molecular.

Positive displacement pumps (PD Pumps) have the following sub classes:

Rotary vane pump, the most common; Diaphragm pump, zero oil contamination; Liquid ring which offer a high resistance to dust; Piston pump, which inflict a fluctuating vacuum; Scroll pump, highest speed dry pump; Screw pump (10 Pa); Wankel pump; External vane pump; Roots blower, also called a booster pump, has highest pumping speeds but low compression ratio; Multistage Roots pump that combine several stages providing high pumping speed with better compression ratio; Toepler pump; and Lobe pumps.

These PD pumps use a mechanism in which they alternate the expansion and sealing off of a cavity. They are used mainly for lower vacuums and can also be paired off with momentum transfer pumps. In the case of pairing, the positive displacement pump starts the momentum and the momentum transfer pump continues the momentum with the higher vacuum.

Molecular or momentum transfer pumps remove air from a chamber by using blades that rotate at a high speed. They work best for higher vacuums. Entrapment pumps actually solidify gases with ionisation, chemicals or very low temperatures before moving them. Consequently, they are normally used for very high vacuums.

Applications for Vacuum Pumps

Vacuum pumps are used in a range of industries, including the manufacturing industry, printing, medical, marine, laboratories, farming, freeze drying, aircrafts, instrumentation, sewage systems and air conditioners.

Classes of Vacuum Pumps

Blower Compressor Side Channel

Side Channel Compressor Blowers deliver oil-free compression of pumped gases. This allows for low maintenance and contaminant free pumps.

Dry Piston Pump

A dry piston pump is a class of vacuum pump that is oil-free.

Vacuum Pump Liquid Ring

Liquid ring vacuum pumps are used for a wide variety of industrial pumping applications including vapour recovery, drawing groundwater from wells or for soil remediation.

In a liquid ring vacuum pump the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal. They are an inherently low-friction design, with the rotor being the only moving part.

Vacuum Pump Radial

Radial vacuum pumps achieve high delivery volumes with very little pulsation.

The frequency inverter integrated on the motor provides the capability of matching volumetric flow exactly to customer requirements.

Vacuum Pump Rotary Vane Oil Free

The Rotary Vane Oil Free Vacuum Pump features design simplicity with only one shaft. The direct drive produces a robust, long-lasting vacuum pump with low maintenance and running costs.

The Rotary Vane Oil Free Vacuum Pump operates completely oil-free with the individual chambers separated by long-life vanes.

Vacuum Roots Booster Pump

Roots booster vacuum pumps are dry (oil free) vacuum pumps that are used in implementations where a high pump speed is required. The roots pump supplements an existing vacuum pump. Together with this backing pump it offers compact partial centralisation.

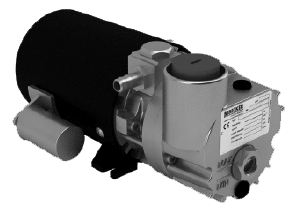

Vacuum Pump Rotary Vane Oil Lubricated

The Rotary Vane Oil Lubricated vacuum pump configuration with a single shaft and direct drive delivers a sturdy and durable pump with low maintenance and low running costs.

These pumps are ideally suited for food processing applications specifically the vacuum packaging of foodstuffs including meat, fish, cold meats and cheese.

Vacuum Pump Screw

The Screw Vacuum Pump consists of two interlocking screw-shaped rotors that rotate in opposite directions.

This high efficiency system draws vapours in which are trapped between the cylinder and screw chambers then compressed and transported to the gas outlet.

Vacuum Pump Side Channel

Using “multi-stage” compression, side channel vacuum pumps generate low-pulsation suction air. Perfected impeller design with curved blades guarantees Optimum efficiency.

They are quiet and compact requiring minimal maintenance whilst delivering high performance.