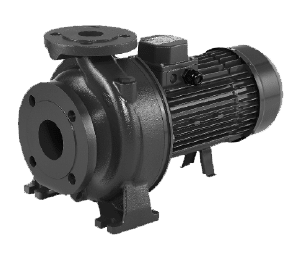

What is an End Suction Single Stage Pump

An End Suction Single Stage pump is the most common class of centrifugal pump. Its simple design has been tried and tested for centuries!

An End Suction Single Stage pump is the most common class of centrifugal pump. Its simple design has been tried and tested for centuries!

The basic principal of the centrifugal pump is fluid flows into the inlet of the pump where it enters the eye of the impeller. The impeller is driven & rotated by mechanical means such as an electric motor or engine etc.

The rotation of the impeller creates centrifugal force which directs the fluid along the impeller vane blades and pushes the fluid to the outer tip of the impeller vane where it enters the pump volute casing.

The volute is shaped in a “snail shell” type shape which directs the fluid around the volute casing, which is then separated by a “cutwater” or “breakwater”. The Cutwater / Breakwater splits the water between the discharge and the recirculating fluid in the volute casing.

Applications for Single Stage End Suction Pumps

Single Stage End Suction Centrifugal pumps are used in water supply, industrial applications for pressure boosting and liquid transfer, ventilation, air-conditioning and heating and agricultural / irrigation applications.

Types of End Suction Single Stage Pumps

Centrifugal Pumps

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

Common uses include water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering.