What is a Peripheral Vane / Regenerative Turbine Pump

A peripheral vane pump (also known as a regenerative turbine pump) is similar to a centrifugal pump, except it operates with a different style impeller. A standard centrifugal impeller has curved vanes that extend from the centre to the edge of the impeller.

A peripheral vane pump (also known as a regenerative turbine pump) is similar to a centrifugal pump, except it operates with a different style impeller. A standard centrifugal impeller has curved vanes that extend from the centre to the edge of the impeller.

The regenerative turbine impeller has rows of vanes on each side of the impellers rim. On the suction side liquid is gathered by the impellers vanes, after making only one revolution in the annular channel, the fluid has a high-velocity that sends the liquid out the discharge. Liquid entering a centrifugal pumps impeller can pass between the vanes only once. Energy is added to the liquid as it travels from the centre of the impeller to the rim. In a regenerative turbine pump liquid recirculates between the impellers vanes. This helical action carries the liquid forward, energy is added to the liquid in a number of impulses by the impellers vanes as it travels from suction to discharge as a liquid builds pressure.

For low flow high head applications regenerative turbine pumps offer better efficiency than centrifugal pumps and can develop several times the discharge pressure of a centrifugal pump having an equally sized impeller.

The regenerative turbine impeller can pump fluid with up to 40% entrained gases without damage from cavitation or any performance loss. Centrifugal pumps are not designed to handle gas in a liquid, gas in a centrifugal pump can create a significant loss in performance causing fluctuating flow, discharge pressure, and unnecessary wear and vibration of the centrifugal pumps internal components. This makes a regenerative turbine pump a great solution where cavitation is a concern.

Applications for Peripheral Vane Pumps

Peripheral Vane pumps are used as pressure boosting pumps. They can be used in industrial applications and in the chemical industry.

Types of Peripheral Vane Pumps

Centrifugal Pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

Common uses include water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering.

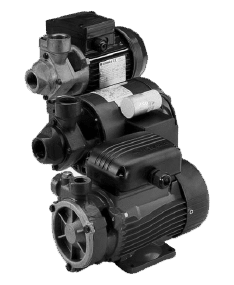

Lowara P Series

The P series from Lowara is a range of peripheral pumps capable of developing high heads using low powered motors.

Read MoreLowara PSA Series

The PSA series from Lowara are asleectionofperipheral pumps capable of developing high heads using low powered motors.

Read MoreLowara SP Series

The SP series consists of close-coupled self-priming pumps with liquid side channel and star impeller.

Read MoreCalpeda T, TP

Close-coupled peripheral pumps (regenerative pumps) with turbine impeller.

T, TP: version with pump casing and lanter bracket in cast iron.

Speck LNY / LSY-2841

The LNY / LSY-2841 series from Speck consists of non-self-priming or self-priming regenerative turbine pumps.

Read MoreSpeck Y / YS-2951

The Y / YS-2951 series from Speck are a range of close-coupled pumps with a mechanical seal.

Read MoreSpeck NPY-2051

The NPY-2051 series is a range of close-coupled pumps with a mechanical seal.

Read MoreSpeck PY-2271 / 2 / 3

The PY-2271/2/3 series of pumps are close-coupled pumps with a mechanical seal.

Read More