A centrifugal pump is only as good as its bearings. Luckily, though, bearings can be maintained to provide many hours of service, simply by knowing what causes them to fail and taking steps to neutralise the cause.

Maintaining the bearings is part of an overall maintenance program that includes the bearings and seals. The purpose is to minimise wear and tear on the pump while maintaining production and reducing down time. Reactive “maintenance,” where one simply waits for something to go wrong and then fixes it, can shorten the life of your pump greatly.

Maintenance should be proactive, preventive and predictive. To predict and prevent bearing failure, you must first know its causes.

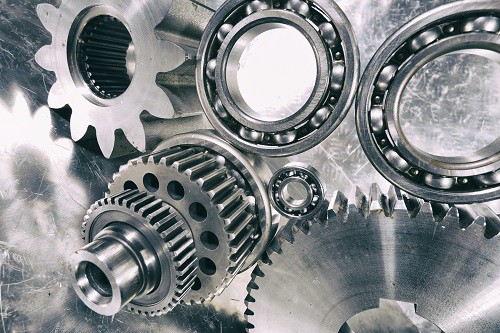

How Bearings Fail

There are two common causes for bearing failure: contamination and ineffective lubrication. Two less-common causes are excessive loading and damaging the bearings before operation, such as during handling or assembly. Often, it is easy to ascertain the root of the problem and fix it.

Sometimes, there are two or more causes for bearing failure within the same system. These should be examined to determine which failures happened in which order. In other words, you must determine the hierarchy of failure within your system.

Contamination

Contamination usually comes from three sources: fluids, metallic particles and dirt or dust. If you keep the bearing in its package and don’t expose it to the elements until it is installed, the bearing is less likely to be exposed to dust or dirt. Also, be sure not to contaminate the bearing when handling it by having grease, dirt or any other contaminants on your hands.

Metallic Particles

Metallic particles usually result from complications of dirt or of substandard lubrication. The particles come from the inside of your pump.

Fluid Contamination

Fluid contamination can be avoided by making sure the seals are doing their job.

Call Pump Solutions Australasia

To make maintenance easier, buy a high quality pump. Call our Perth office: 1300 922 973 today.