Equipment Details

Pump Make & Model

Southern Cross 125×100-250/236

Investigation and Findings

Upon attending the site, we investigated a reported leak in the above pump. It was determined that the pump seal plate was leaking. Upon disassembly of the pump, we observed that the seal plate had suffered severe erosion, which resulted in a hole, causing the leak.

Further inspection revealed that the pump volute exhibited significant internal corrosion. Additionally, the mechanical seal flush port was entirely closed off and sealed due to corrosion.

The motor was run without an impeller or load, during which we noted that the bearings were noisy. Based on this, we determined that the best course of action was to transport the pump to our service centre for a full assessment.

Assessment and Repair Plan

- A localized sandblast was performed on the seal plate to further expose the erosion and assess the condition of the mechanical seal stationary journal and O-ring seat.

- It was confirmed that:

- The erosion on the seal plate can be repaired.

- The mechanical seal stationary journal has some pitting but remains usable.

- The O-ring seat is in good condition.

- The impeller efficiency ring and volute wear rings were measured and found to be within tolerance.

Proposed Repairs

- Grit blast the internal volute and seal housing.

- Repair the seal housing using Loctite Magic Metal.

- Apply a Loctite ceramic coating to the pump’s internal casing to prevent future corrosion.

- Replace the mechanical seal and casing O-ring.

- Replace motor bearings and seals.

- Polish the pump shaft.

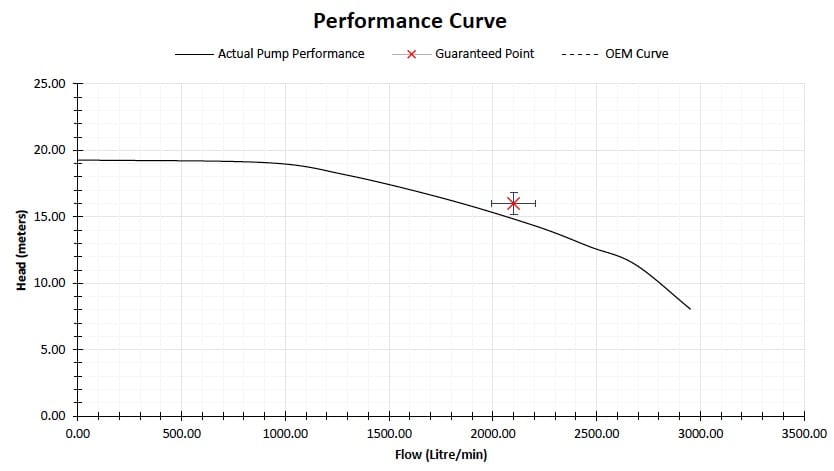

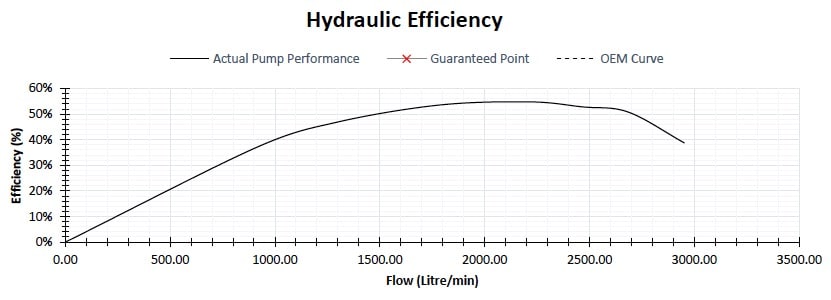

- Reassemble the pump and conduct testing at our test facility to ensure proper operation.

Reinstallation Plan

Once repairs and testing are completed, we returned to site to reinstall the pump and verify its performance on-site.

Conclusion

The client followed the above advice and we have repaired the pump. it’s now back in service and running well.

Pump Curves