Pumps as a type of machine come in many different shapes and sizes and are used for a variety of reasons in a plethora of different industries in Perth. Within the group of pumps, there too are various kinds that operate in certain ways to best serve the function they were intended for. One of these types of pumps that are among the most useful is the centrifugal pump. Operating on the concept of, as the name implies, centrifugal force and rotating internal mechanisms, this type of pump is invaluable to a number of different fields.

How It Works

The basic concept behind the centrifugal pump is not a complicated one, but rather effective. The pump is set up with a hollow casing with vanes and impellers rotating inside of it. This rotation is facilitated by a running motor, which creates the kinetic energy necessary to move the fluid inside. When the vanes and internal components spin, the water or other liquid inside of the machine is pumped through the piping.

The basic concept behind the centrifugal pump is not a complicated one, but rather effective. The pump is set up with a hollow casing with vanes and impellers rotating inside of it. This rotation is facilitated by a running motor, which creates the kinetic energy necessary to move the fluid inside. When the vanes and internal components spin, the water or other liquid inside of the machine is pumped through the piping.

The speed of the motor varies by model, but the pump is able to propel water and other viscous fluids at fast speeds. In addition, pressure is created through the centrifugal force inside of the pump, allowing the water to be discharged at even faster flow rates. This cycle of pumping continues, using both the power generated by the motor and the potential energy converted into kinetic energy by the hydraulic pressure inside of the mechanism.

Different Kinds

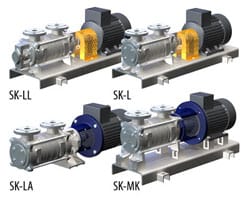

While all centrifugal pumps operate under the same basic premises, there are slight variations among different kinds and models. Generally speaking, there are three main types based on the shape of the vanes inside of the core: straight vane, curved vane and volute.

Straight vanes are the simplest and generally the most common. They contain several blades that spin inside the main part of the pump. Acting on the key function of centrifugal pumps to use the force of the spinning blades to propel water, these vanes are effective in almost any scenario.

Curved vane designs still work in the same fashion as their normal counterparts do, but the entirety of the device is shaped differently. Both the casing and the individual blades are curved; the blades that match the curved shape of the impeller force the water into the centre before it is channelled through the discharge pipe. The advantage to using curved vane pumps is that they can more easily fit into different and sometimes awkward places, making them practically more adaptable.

The final kind of centrifugal pump is the volute design. This model uses a single-plane inside of it and funnels the water or other fluid into a spiral shape. The casting is designed as such as well to fit impeller and water is pushed out at the end of a series of expanded intervals. Like the curved vane design, this kind of centrifugal pump is most useful in places that require a different shape of pump rather than the traditional one.

Top Uses

With the simplicity, variety of kinds and power behind the operation of a centrifugal pump, it has found many different uses in a variety of fields and industries. Water is the most common fluid that is transported through this type of pump, so any kind of industry that utilises the mass flowing of water has great use for centrifugal pumps.

The construction business in particular relies heavily on machines like pumps, and centrifugal ones are the most commonly used. This is primarily because many big construction sites require the transport of water. The mining industry uses this type of pump for the same reason.

Water is not the only thing that can be pumped through centrifugal pumps however. Since other materials like oil and natural gas can be transported in this way too, industrial and other mining facilities can make use of this kind of pump. Sewage is also commonly pumped through this type of machine.

Go Around, Go Around

Centrifugal pumps are some of the most useful and powerful pumps that are on the market. They operate on the simple premise of using a motorised impeller to spin vanes inside of the casing of the pump, generating centrifugal force and pressure in the water or other liquid that propels it forward at great speeds. With a wide selection of types and sizes, it is no wonder that it has found its way into many different fields, including the construction, mining, waste removal and other industries.

To learn more about centrifugal pumps and about how to acquire top-quality pumps for your industry or business, call us on 1300 922 973.