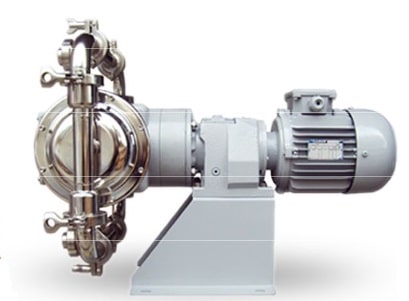

Diaphragm pumps are a mainstay in the chemical industry throughout Australia. A diaphragm pump is a pump that uses one or two diaphragms in tandem with check valves to pump fluids.

How They Work

The diaphragm or diaphragms make the chamber smaller by pushing in towards the centre, pushing out fluids. When a diaphragm pulls away from the centre, it creates a vacuum, pulling in fluids. The fluids are directed by check valves that only allow the fluid to move in one direction. The fluid is pulled from one direction and pushed out the other.

There are numerous qualities that make diaphragm pumps perfect for the chemical industry. They are capable of being used with high or low flow rates. Flow rate is easily adjusted by the diameter and the stroke length of the diaphragm.

Diaphragm pumps also have great dry pumping characteristics. They are also able to efficiently pump sludges and slurries, even those with high solid content. They can be used for high or low pressure pumping.

Uses in the Chemical Industry

The chemical industry uses a wide range of diaphragm pumps due to the different characteristics of chemicals and fluids. Diaphragm pumps can handle the most flammable, aggressive, viscous and abrasive fluids with ease.

To allow a diaphragm pump to handle a certain chemical, the pump materials are “matched” to the chemicals. Pumps are available in different materials, in a wide range which allows them to pump virtually any chemical on the market.

Double diaphragm pumps, also called Air Operated Double Diaphragm (AODD) pumps, use compressed air to move the diaphragms. They are seen by many as the safest design for pumping more aggressive chemicals. AODD pumps are limited to 6m suction lift, but they can operate with as much as a 160 metre discharge head.

At Pump Solutions Australasia, we have chose Ran Pumps to make our AODD pumps. They are the finest in the world and are made in Turkey.

To learn more about any of our inventory or to place an order, call Pump Solutions Australasia today: 1300 922 973.