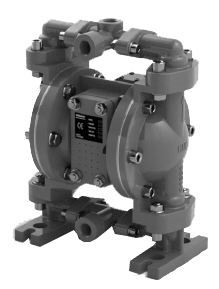

Here are some answers to frequently asked questions about air operated diaphragm pumps.

Which kind of pump do I buy?

There is no “one size fits all” answer here. The kind of pump to buy is dependent upon what it will be used for. Is your fluid clear or is it slurry? Is it neutral or corrosive? Is it a low-viscosity or high-viscosity fluid. Fluids with high viscosity require a more strong and durable pump.

You will also need to know your desired flow rate, as it will determine the size of your pump. The pressure gradients on both the inlet and outlet will affect your choice, as will the projected pressure and temperature.

What fluids are appropriate for diaphragm pumps?

A diaphragm pump can move almost any kind of fluid, from water to oil to acid. They are often used for high viscosity fluids such as resins, surfactants, hand lotions and gear oils.

Are there any “special cases”?

Chemicals such as bleach, acids and caustics should be transported with a plastic pump. Chemicals that aren’t appropriate for a plastic pump include polyol, isocyanate and styrene.

What maintenance factors are involved?

Luckily, it is easy to maintain a diaphragm pump and keeping it in perfect condition. Check the air filter regularly to maintain the high air quality that ensures efficient performance. Check the elastic components of the pump once every two months for uneven wear.

The inlet and outlet should both be checked often and kept free of debris. It is also necessary to monitor the torque of the bolts on the pump. That is all it takes to keep a diaphragm pump running at high efficiency.

What industries typically use diaphragm pumps?

Diaphragm pumps are versatile and are used by a lot of diverse industries in Perth and across Australia. These include but are not limited to: the printing and ink, food and beverage, cleaning, construction, water, mining, petrochemical and metal fabrication industries.

Call 1300 922 973 to learn more about diaphragm pumps.