Up to speed with the moving market …

Bringing you the latest news, insights and industry commentary from leading brands and thought-leaders, our news blog focuses on emerging innovations, new developments and community perspectives from around the globe – keeping you up to date with the latest industry makers and shakers.

June 13, 2024

June 13, 2024How a Submersible Pump WorksSubmersible pumps, commonly referred to as sub pumps or electric submersible pumps (ESPs), are essential devices …

January 18, 2021

January 18, 2021Gorman-Rupp has updated our 2” T Series pumps to incorporate the following Super T Series features:External, shimless clearance adjustmentFour-point back …

November 10, 2020

November 10, 2020Manufactured to the same exacting standards of other Gorman-Rupp products and built specifically for use on petroleum products such as …

June 1, 2018

June 1, 2018We import the finest pumps into Australia from around the world. What you may not know is that we also …

May 7, 2018

May 7, 2018Gorman Rupp are one of the largest manufacturers of centrifugal pumps in the world. Based in the US, they manufacture …

May 4, 2018

May 4, 2018Fluid-o-Tech are a world-renowned manufacturer of rotary vane pumps. One of their more popular is the TH 500-1000 Series Stainless …

April 30, 2018

April 30, 2018Grundfos CR vertical multistage centrifugal inline pumps can be used for a wide range of industrial solutions in nearly every …

April 26, 2018

April 26, 2018RAN Pump is a relative newcomer to the “club” of elite international pump manufacturers, but they have done a great …

April 23, 2018

April 23, 2018The Gorman Rupp Ultra V Series comes in three sizes: 80 mm, 100 mm and 150 mm. They have a …

April 20, 2018

April 20, 2018Tsurumi KE/KS/KW Series bar screens are front-screen, automatic type bar screens that are used in the screening process for wastewater. …

April 17, 2018

April 17, 2018Tsurumi have added two Tsurumi KTZ Series 15 kW submersible pumps in their Flagship KTZ series. Before the introduction of …

March 29, 2018

March 29, 2018Leading pumps provider Pump Solutions Australasia enables Perth area businesses and residents to make their own soda for a fraction …

March 22, 2018

March 22, 2018RAN Pump is a relative newcomer to the international pump industry, but they have made a significant impact in their …

March 16, 2018

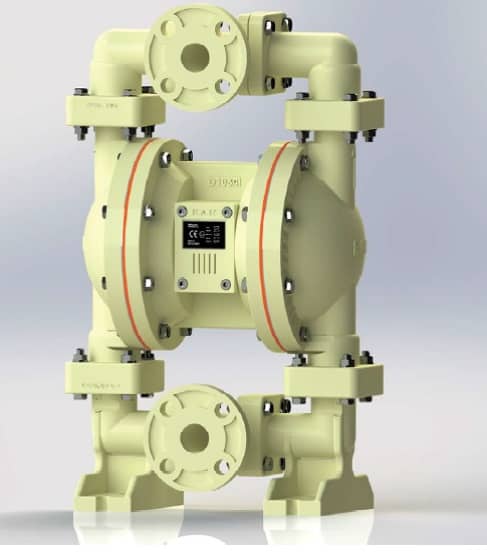

March 16, 2018Graco is a US manufacturer that makes air operated double diaphragm (AODD) pumps. They were established in 1926. Their first …

March 14, 2018

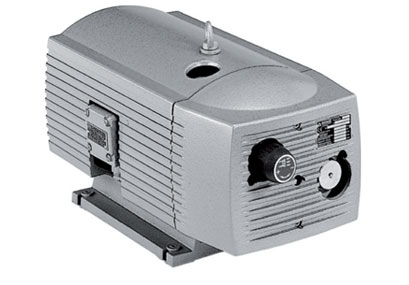

March 14, 2018We import Becker Pumps because they are one of the best manufacturers in the world. Based in Germany, Becker are …

March 8, 2018

March 8, 2018Fluid-O-Tech are a highly-respected pump manufacturer based in Italy. They have been in business since 1948. We are proud to …

March 2, 2018

March 2, 2018We have done business with Tsurumi Pumps for a long time. They are a manufacturer that has been in business …

February 27, 2018

February 27, 2018Tsurumi Pumps have been making high quality pumps since they were established in 1924, in Japan. Their submersible pumps have …

January 22, 2018

January 22, 2018Xylem Pumps is the parent company for Lowara Pumps. They are one of the largest and most innovative pump manufacturers …

December 29, 2017

December 29, 2017The Fluid-o-Tech 4000 series consists of rotary vane pumps made of stainless steel. They feature the patented Fluid-o-Tech Rotoflow technology. …

December 29, 2017

December 29, 2017The Tsurumi MG Series is a series of pumps that is designed for the sewage industry. Tsurumi is known for …

December 25, 2017

December 25, 2017RAN Pumps, or RAN Pompa, are located in Istanbul, Turkey. They have only been in business since 2000, but they …

December 22, 2017

December 22, 2017Becker is an international pump manufacturer located in the US that is well-known and respected for their vacuum pumps. One …

December 20, 2017

December 20, 2017Fluid-o-Tech has been making high quality pumps for nearly 70 years. They were founded in 1948 in Italy by Franco …

December 18, 2017

December 18, 2017When it comes to submersible pumps, Tsurumi is the biggest name in the business. One of their most popular varieties …

December 13, 2017

December 13, 2017At Pump Solutions Australasia, we import the best pumps from all over the world into Australia. We have chosen this …

December 8, 2017

December 8, 2017Fluid-o-Tech pumps have a sterling reputation in the food and beverage industry. But did you know that the same characteristics …

December 6, 2017

December 6, 2017Some of you may have heard this term and some may not: trash pumps. These pumps are designed for dewatering …

December 4, 2017

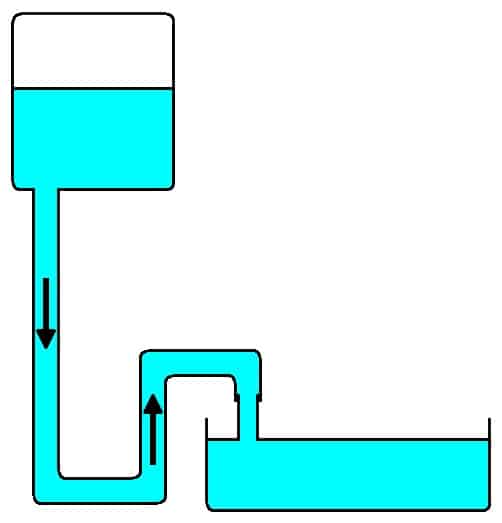

December 4, 2017As a prolific importer of pumps in Australia, we thought it would be helpful to define some of the terms …

December 1, 2017

December 1, 2017Established in 1990, technology has come a long way. Common people weren’t even allowed to use the internet yet and …